Li-oscillating cutters li fetotse liindasteri tse fapaneng ka ho fana ka ts'ebetso e nepahetseng le e sebetsang ea ho itšeha.Har'a mefuta e fapaneng ea li-cutter tse thothomelang 'marakeng, li-cutter tse peli, tse otlolohileng le tse otlolohileng li ratoa haholo.Sengoliloeng sena se ikemiselitse ho fana ka papiso e tebileng ea mefuta ena e meraro ea lisebelisoa tse sisinyehang, e shebane le likarolo tsa eona, melemo le lits'ebetso.

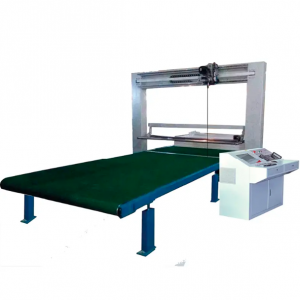

Mochini oa ho itšeha oa li-blade tse peli

Li-win-blade vibratory cutters li tsebahala ka ho ikamahanya le maemo le ho seha ka katleho.Joalokaha lebitso lena le bontša, e na le li-blades tse peli tse tsubehang ka nako e le 'ngoe li lebile mahlakoreng a fapaneng.Moqapi ona o ikhethang o eketsa lebelo la ho itšeha le ho ntlafatsa ho nepahala.Li-win-blade vibratory cutters li loketse ka ho khetheha mesebetsi e hlokang ho nepahala ho phahameng, joalo ka ho seha libopeho tse rarahaneng le lipaterone linthong tse kang lehong, polasetiki le tšepe.

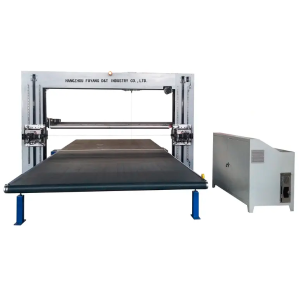

Sekhahla se thothomelang se tshekaletseng

Liseha tse tšekaletseng tse oscillating, tse tsejoang hape e le li-oscillating cutters, li na le lehare le le leng le tsamaeang ho ea holimo.Mofuta ona oa "vibratory cutter" hangata o sebelisoa lits'ebetsong tse hlokang liropo tse telele, tse tsoelang pele, joalo ka ho kuta likotoana tse kholo tsa lesela kapa ho seha foam e teteaneng.Horizontal vibration cutters ba nkoa e le ba bohlokoa haholo bakeng sa botsitso le bokhoni ba bona ba ho hlahisa bohloeki, esita le ho khaola.

Sekhahla se thothomelang se otlolohileng

Ha ho bapisoa le li-cutter tse tšekaletseng, li-vibration cutters li na le mahare a eang holimo le tlase.Mofuta ona oa "vibratory cutter" o atisa ho sebelisoa bakeng sa mesebetsi e kenyelletsang ho seha lintho tse otlolohileng, joalo ka ho poma wallpaper, ho seha liphahla ka khateboto, kapa ho seha masela a masesaane.Mechini ea ho itšeha ea oscillating e otlolohilengfana ka taolo e ntle le ho nepahala, ho li etsa tse loketseng bakeng sa ts'ebetso e bonolo le e rarahaneng ea ho itšeha.

Bapisa 'me u sebelise

Ha ho tluoa tabeng ea ho seha ka katleho, li-win-blade vibratory cutters li etella pele pakete ka lebaka la moralo oa tsona oa mafahla.E lumella ho potlakisa ho itšeha ka lebelo le ho fokotsa kotsi ea ho jama ha lehare.Ntle le moo, ho feto-fetoha ha seha sehare sa li-oscillating tse peli ho etsa hore e tšoanelehe bakeng sa lits'ebetso tse fapaneng, ho kenyeletsoa ho etsa mapolanka, ho etsa tšepe le merero ea DIY.Ka lehlakoreng le leng, li-cutters tse otlolohileng tsa vibration li ipabola mesebetsing e hlokang liropo tse tsoelang pele le tse atolositsoeng.Ho tsitsa ha eona le bokhoni ba ho sebetsana le lisebelisoa tse kholo le tse thata ho etsa hore e be khetho ea pele liindastering tse kang mokhabiso oa ka hare, likoloi le liphutheloana.Qetellong, ts'ebetso ea ho seha ho ea holimo le tlase ea seha se otlolohileng sa vibrate se se lumella ho phethela mesebetsi e kenyelletsang ho seha ho nepahetseng hantle.E sebelisoa hangata ho masela, khatiso, bonono le mesebetsi ea matsoho le liindasteri tse ling.

ha re phethela

Ka bokhutšoanyane, lisebelisoa tse thothomelang tse mahlakoreng a mabeli, lisebelisoa tse sisinyehang tse tšekaletseng, le lisebelisoa tse thothomelang tse otlolohileng e 'ngoe le e 'ngoe e na le litšobotsi le melemo ea eona e ikhethang.The dual-blade oscillating cutter e fana ka mefuta-futa le lebelo le ntseng le eketseha la ho itšeha, ha sehahi se oscillating se sehang se fana ka botsitso le katleho nakong ea ho itšeha ho tsoelang pele.Ho sa le joalo, li-oscillating cutters tse otlolohileng li sebetsa hantle haholo ts'ebetsong ea ho itšeha e hlokang ho nepahala.Qetellong, khetho ea hore na o tla sebelisa sehahi sa vibratory sefe se itšetlehileng ka ts'ebeliso e khethehileng le liphetho tse lakatsehang tsa ho itšeha.Leha ho le joalo, mefuta ena e meraro ea li-cutters tse thothomelang ntle le pelaelo e fetotse indasteri ea ho itšeha 'me e tsoela pele ho phetha karolo ea bohlokoa mafapheng a fapaneng.

Nako ea poso: Oct-18-2023